First, almost 20 tons of glass are melted in a honeycomb-shaped mold, inside a giant rotating oven at 1160ºC for 4 hours. The temperature is cooled rapidly to 900ºC and then it cools slowly for three months to avoid thermal strains. After that, rough grinding of the front and back surfaces is performed.

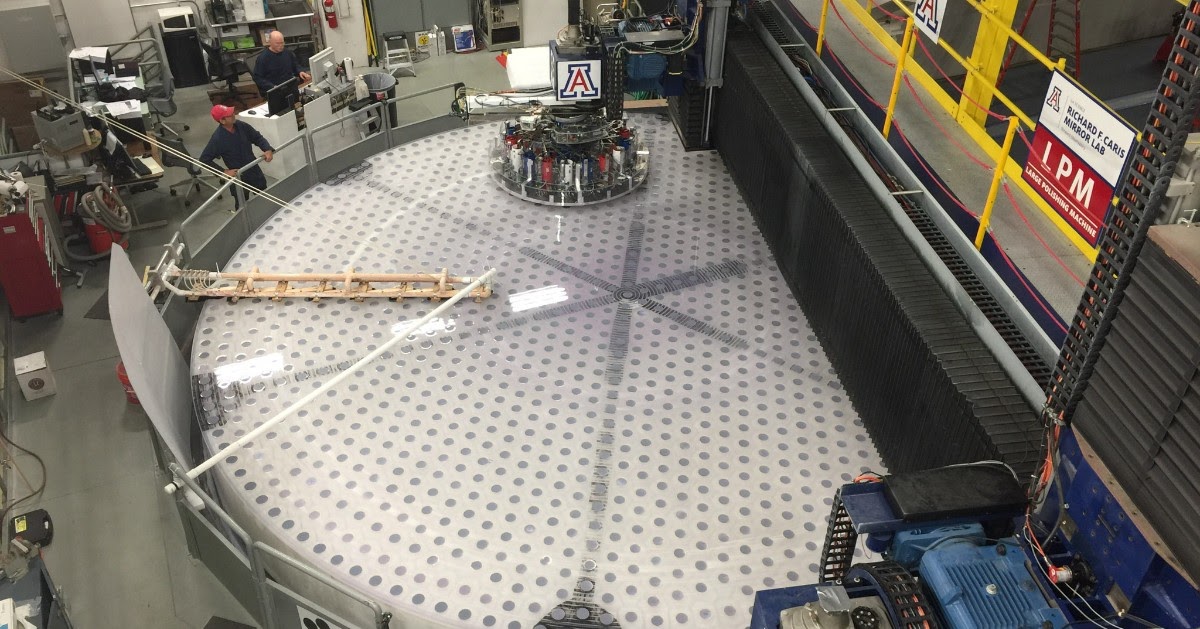

The front surface is polished with computer controlled tools to achieve optical tolerances that are constantly measured to assure that it is precisely figured.

At the end of polishing, it’s placed on a complex support system and the surface is coated with a thin layer of aluminum to attain maximum reflectivity. The mirror is transported to a local storage facility, where it will remain until the GMT is assembled.